Ever wonder what the different types of rubber lining are used for?

Rubber lining is a process of protecting equipment from wear and corrosion. There are many different types of rubber lining, each with its advantages and disadvantages. It can be a difficult decision to choose the right type of rubber lining for your needs.

That’s why we’ve created this guide! We want to help you make the best decision when choosing rubber lining for your business. We’ll go over the different types of rubber lining and explain how they’re used in wear and corrosion protection.

Different Types of Rubber Lining Solutions for Industrial Businesses

Rubber has various properties that make it an ideal material for industrial uses. It is resistant to abrasion, corrosion, and impact, making it ideal for lining pipes, tanks, and other equipment. There are many types of rubber lining solutions. Each type of rubber has its advantages and disadvantages, so choosing the right type for each application is essential.

Soft Natural Rubber Lining

If you’re looking for a lining option for your tank holding inorganic chemicals, soft natural rubber is a good choice. It’s corrosion-resistant and can withstand many abrasive materials – plus, it’s commonly used for hydrochloric acid applications. However, remember that this type of rubber is not suited to handle strong oxidizing agents. But if you don’t need that capability, soft natural rubber is an excellent and durable choice for your tank lining needs.

Neoprene Rubber Lining

Neoprene rubber is a versatile and durable synthetic rubber used in various applications. It is resistant to heat, oil, and chemicals, making it an ideal choice for many industrial and commercial uses.

Neoprene rubber also has a longer lifespan than many other types of rubber, making it a cost-effective choice for long-term projects. In addition to its practical benefits, neoprene rubber has a unique aesthetic appeal. Its black color and smooth texture make it a modern look popular in many industries. Whether you need a durable material for a demanding application or a stylish finish for your product, neoprene rubber is an excellent choice.

EPDM Rubber Lining

EPDM (ethylene propylene diene monomer) rubber is a popular choice for many applications because it is very versatile. It can resist ozone and sunlight, oxidizing chemicals, non-flammable hydraulic fluids, pure aniline, fire extinguisher liquids, acids, hot water, and steam. However, it is not suited for petroleum-based products. It makes it a good choice for various applications, but you’ll need to choose something else if you want to use it with petroleum products.

Nitrile Rubber Lining

Thanks to its versatile properties, nitrile rubber is an increasingly popular choice for various industrial uses. Nitrile rubber is synthetic rubber resistant to petroleum products and operates effectively at high and low temperatures. While it can withstand temperatures up to 80 degrees Celsius, it is also less ozone resistant than other types of synthetic rubber.

Nitrile rubber is stronger than natural rubber and has better abrasion resistance, making it an ideal material for many industrial applications. In addition, nitrile rubber lining is an effective way to protect against corrosion in storage tanks and pipelines.

Which Rubber Linings Are Best for Each Business

The best rubber lining for each business depends on the specific needs.

For example, a company that manufactures food products will need a different type of rubber lining than a company that manufactures chemicals. The food company will need a rubber lining that is FDA-approved and can withstand the high temperatures of the food-production process.

On the other hand, the chemical company will need a rubber lining resistant to the corrosive effects of chemicals.

In addition, each company will need to consider their products’ specific dimensions and shapes when choosing a rubber lining. A custom-made rubber lining may be the best option for some businesses, while others may be able to find an off-the-shelf solution that meets their needs.

Ultimately, the best rubber lining for each business is the one that meets the specific needs of that business.

Rubber Lining Process

The rubber lining process is a crucial step in ensuring the longevity and effectiveness of many different types of industrial equipment.

Applying a rubber layer to the surface of metal pipes and tanks makes it possible to create a barrier resistant to corrosion and abrasion. In addition, rubber lining can help to insulate against heat and noise, and it can also provide anti-static properties.

The specific method used for rubber lining will vary depending on the type of equipment being lined. Still, the process typically involves bonding the rubber to the metal surface using adhesives or mechanical fasteners.

Benefits of Rubber Linings

Industrial rubber linings have many benefits.

- They are resistant to abrasion, corrosion, and chemical attack.

- They are also easy to install and repair.

- In addition, rubber linings can prolong the life of the equipment and reduce noise levels.

Industrial rubber linings are used in various applications, including food processing, pharmaceuticals, and chemical manufacturing.

Rubber linings can be applied to tanks, pipes, valves, and other equipment. They provide a durable barrier that protects the underlying metal from corrosion and wear. In addition, rubber linings can insulate against noise and vibration.

As a result, they are an important part of many industrial operations. Rubber linings have many benefits, making them an essential part of many industries.

Cost for Rubber Linings

The cost of rubber linings varies. It depends on several factors:

- type of rubber used,

- the thickness of the lining,

- and the size of the area to be lined.

However, rubber linings are generally very cost-effective compared to other lining materials.

Rubber is an extremely durable material that can withstand various conditions, making it ideal for use in areas subject to high wear and tear. In addition, rubber linings are easy to install and require minimal maintenance, making them a popular choice for many businesses.

When considering the cost of rubber linings, it is important to factor in the long-term savings you can achieve using this durable and low-maintenance material.

About Atlas Wear Solutions

High abrasive environments require rubber lining to reduce wear, shock, and corrosion. For the best results of rubber lining, the correct surface preparation and installation are important. We have experienced crews that can perform installations in our workshop or at your site.

We use a variety of rubber for wet and/or dry abrasion, ensuring you have the best solution. Our team has over 30 yrs experience, and with their vast knowledge, they can fabricate and line any component for you.

Our Rubber Lining Services

- We build expansion joints, gaskets & concrete load socks to your specifications.

- We line screens, launders, and chutes.

- We use and supply skirt rubber, food-grade, acid, oil, and chemical-resistant rubbers.

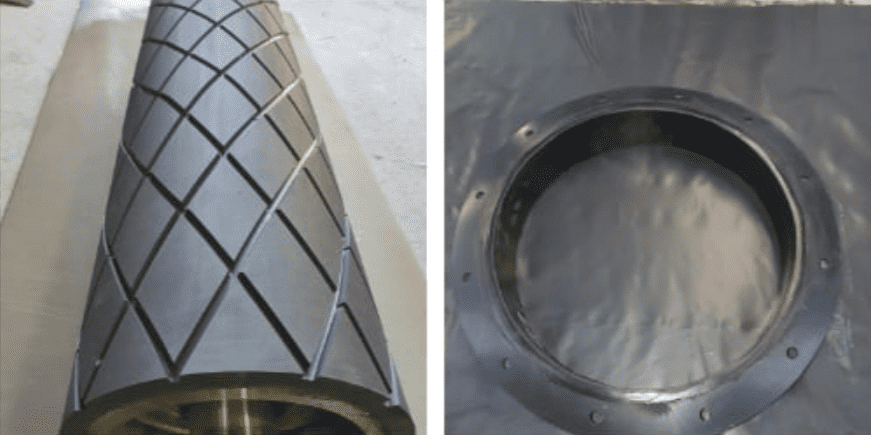

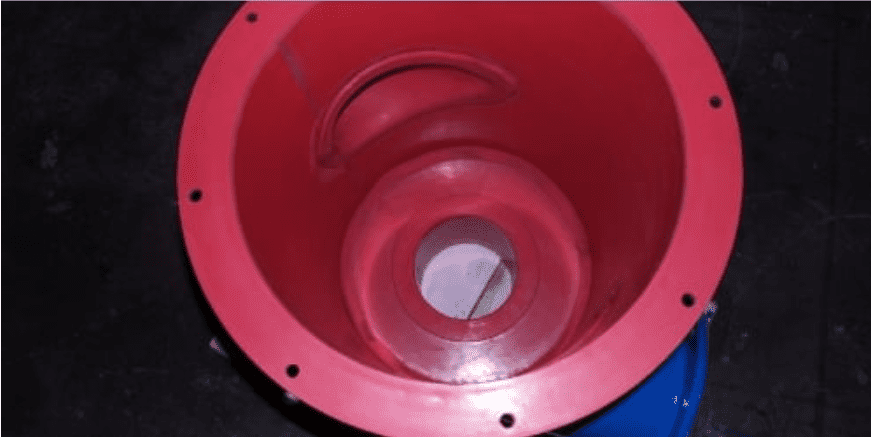

- We fabricate new hydro cyclones in various sizes and rubber line them.

- We manufacture fishtails and spigots to suit your cyclones.

- We supply exchange cyclones parts and strip, repair, and reline your old cyclones.

- We have mining hoses custom-built to your specifications.

- Pulley Lagging – smooth, diamond groove, ceramic, and FRAS (Fire Resistant Anti-static) lagging available.

Frequently Asked Questions

Which Type of Rubber Is Used as Lining Material?

Two main types of rubber are commonly used as lining materials: natural rubber and synthetic rubber.

Natural rubber is made from certain trees’ latex and has excellent wear resistance and flexibility. Synthetic rubber is made from petroleum-based products and offers superior heat and chemical resistance.

Both types of rubber have advantages and disadvantages, so the type used as lining material will depend on the application’s specific needs. In general, natural rubber is more suitable for applications that require high levels of flexibility. In contrast, synthetic rubber is better suited for applications requiring high heat or chemical resistance levels.

How Is Rubber Lining Done?

Rubber lining applies a layer of rubber to the inside surface of a metal tank or container.

The purpose of rubber lining is to protect the metal from corrosion, abrasion, and chemical attack. Rubber lining is often used in tanks that store acids, alkalis, and other corrosive chemicals. The thickness of the rubber lining ranges from ⅕ inch to 20m. In some cases, multiple layers of rubber are used for added protection.

The first step in rubber lining is to clean and prepare the surface of the metal. Next, a primer is applied to the metal to promote adhesion between the metal and the rubber. The final step is to apply the rubber liner using either a spray gun or a roller.

Rubber lining is a specialised process that requires skilled workers and careful attention to detail. When done correctly, it can help extend the life of a metal tank or container by many years.

What Is Rubber Lining Used For?

Rubber lining is a versatile tool used in various settings, making it an important part of many businesses and industries.

Rubber lining is a process in which a substance like rubber is applied to the inner surface of something else. It can be done for several reasons, but one of the most common is to protect the item from substance contamination.

For example, rubber lining may be used on pipes that carry hazardous materials to prevent those materials from coming into contact with the pipe itself. In addition, rubber lining can also be used to improve an item’s durability or make it more resistant to wear and tear. As such, it is often used on items subject to a lot of wear and tear in industrial workstations.

Difference Between Hard Rubber Lining and Natural Rubber Lining

Industrial rubber linings serve various purposes, from protecting exterior surfaces from abrasion to containing corrosive chemicals. There are two main types of rubber linings: natural and hard.

Natural rubber is made from the sap of rubber trees, while hard rubber is a synthetic product. Both types of rubber have unique properties that make them suitable for different applications.

Hard rubber is more resistant to abrasion and chemicals than natural rubber but is also more brittle and less flexible. On the other hand, natural rubber is more flexible and resistant to tearing, making it ideal for lining surfaces subject to constant movement.